John Deere 826 Snowblower Parts Manual

- 1981 John Deere 826 Snowblower Parts Diagram

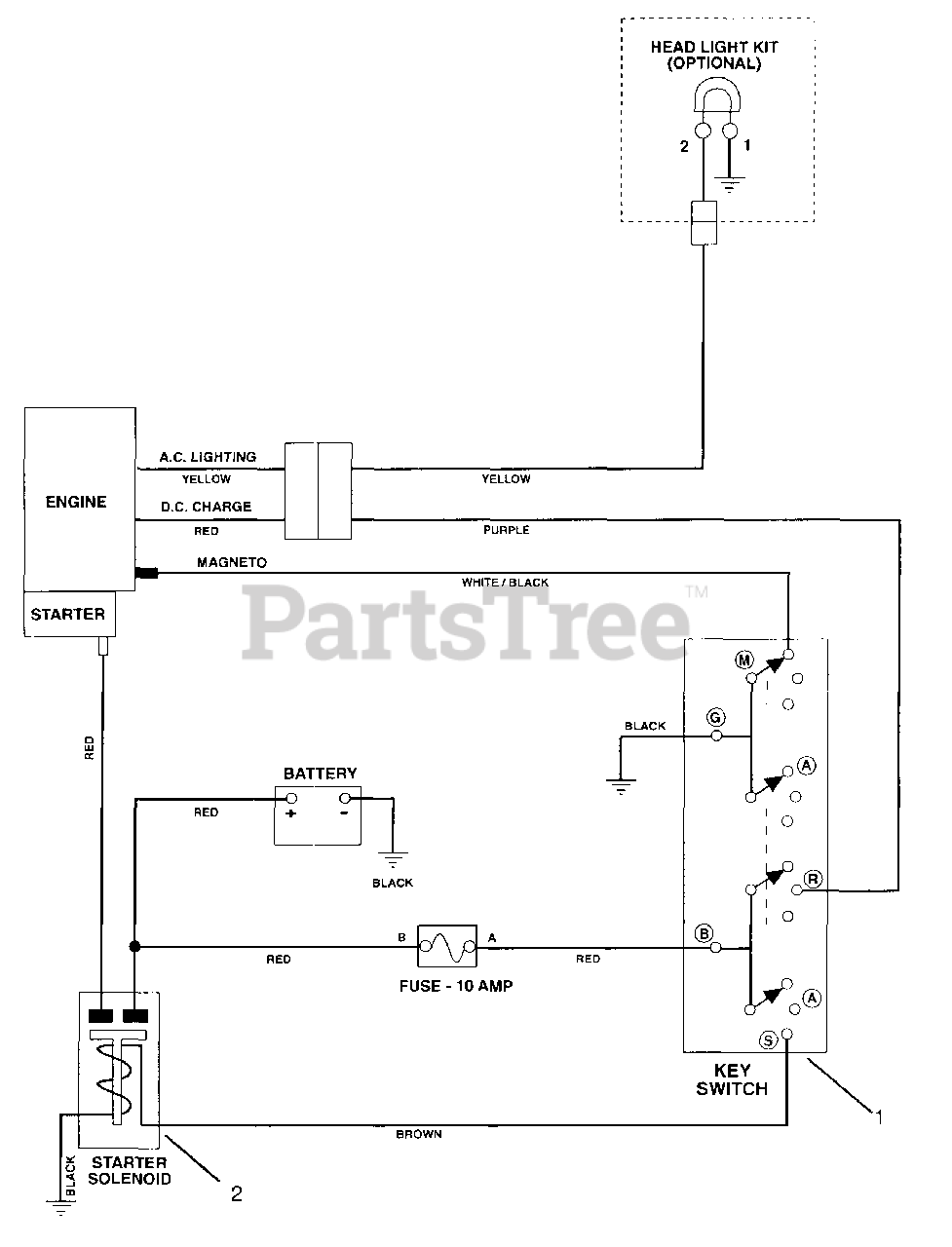

- 826 John Deere Snowblower Engine

- John Deere 826 Snowblower Repair Manual

- 826 John Deere Snowblower Diagram

Service

Engine Warranty Maintenance Statement

Maintenance, repair, or replacement of the emission control devices and systems on this engine, which are being done at the customers expense, may be performed by any nonroad engine repair establishment or individual. Warranty repairs must be performed by an authorized John Deere dealer.

- JOHN DEERE 526, 726, 732, 826, 832, 1032 WALK-BEHIND SNOWBLOWERS repair manual & service manual is in pdf format so it will work with computers including WIN, MAC etc.You can Easily view, Navigate, print, Zoom in/out as per your requirements. We accept Paypal and All Credit Cards. If you have any questions regarding this Manual. Please contact us.

- John deere 826 snowblower service manual Click here to get file. John deere 526, 726, 732, 826, 832, 1032 walk behind snowblowers service repair manual. 10 inspect drive bes remove and replace bes as required. This image has been resized click this bar to view the full image.

- HIFROM Carburetor Carb with Mounting Gasket Fuel Line Fuel Filter Replace for John Deere Snow Blower Thrower TRS22 TRS24 TRS26 TRS27 TRS32 Snow Blower Thrower. 3.6 out of 5 stars 8. Replacement Belt for John Deere 826 Snowblower M82612 M45491 Auger (1/2'x36') $11.24 $ 11.

- D&D PowerDrive M82612 John Deere 826 Snowblower M45491 Auger Replacement Belt, Rubber. 4.4 out of 5 stars 20. Get it as soon as Wed, Nov 25.

Find parts & diagrams for your John Deere equipment. Search our parts catalog, order parts online or contact your John Deere dealer.

Service Intervals

Before Each Use Or As Required | · Check engine oil. · Check hardware. · Adjust belt guides. · Replace auger drive belt. · Replace traction drive belt. · Replace shear bolt. · Adjust chute worm drive. · Adjust chute control rod. · Adjust spout control lever. · Adjust carburetor. · Adjust friction wheel. · Replace friction wheel. · Reverse scraper blade. · Clean fuel cap vents. · Check gearbox lubricant. |

After First 2 Hours Of Operation | · Change engine oil. · Check hardware. · Lubricate snowblower. · Check auger drive belt adjustment. · Check traction and auger cable adjustments. |

10 Hours | · Lubricate snowblower |

25 Hours Or At End Of Season | · Adjust auger drive belt · Check spark plug. · Change engine oil. · Check tire pressure. · Lubricate friction disk hub zerk. · Check auger and traction cable adjustments. · Lubricate auger shaft. · Lubricate wheel axle. |

Service Record

Avoid Fumes

| c CAUTION: Avoid injury! Engine exhaust fumes can cause sickness or death: · If it is necessary to run an engine in an enclosed area, use an exhaust pipe extension to remove the fumes. · Always try to work in a well ventilated area. |

Engine Oil

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following John Deere oil is preferred:

The following John Deere oils are also recommended, based on their specified temperature range:

· TURF-GARD® (SAE 10W-30)

· PLUS-4® (SAE 10W-30)

· TORQ-GARD SUPREME® (SAE 30)

Other oils may be used if above John Deere oil is not available, provided they meet one of the following specifications:

· SAE 5W-30-API Service Classification SG or higher

· SAE 10W-30-API Service Classification SG or higher

SAE 30-API Service Classification SC or higher

Grease

Use grease based on the expected air temperature range during the service interval.

The following greases are preferred:

· John Deere Moly High Temperature EP Grease.

· John Deere High Temperature EP Grease.

· John Deere GREASE-GARD.

Other greases may be used are:

· SAE Multipurpose EP Grease with 3 to 5 percent molybdenum disulfide.

· SAE Multipurpose EP Grease.

· Greases meeting Military Specification MIL-G-10924C may be used as arctic grease.

TS1417

Checking Engine Oil

1. Park snowblower on a level surface.

M96036

2. Remove dipstick (A). Wipe it.

3. Check engine oil:

· Install and tighten dipstick.

M71567

· Remove dipstick. Check oil level. Oil should be between ADD and FULL marks on dipstick.

4. Add oil if necessary. (See Engine Oil in this section for correct oil.)

5. Install and tighten dipstick.

Changing Engine Oil

NOTE: If you do not operate snowblower 25 hours during season, change oil at end of season.

1. Park snowblower on a level surface.

2. Run engine a few minutes to warm oil.

3. Stop engine.

M96037

4. Remove drain cap (A).

M96036

5. Remove dipstick (B).

6. Drain oil into container. Install drain cap.

7. Add 0.6 L (19 oz) of oil through dipstick tube. (See Engine Oil in this section).

8. Install and tighten dipstick.

M71567

9. Remove dipstick. Check oil level. Oil should be between ADD and FULL marks on dipstick.

10. Install and tighten dipstick.

Gapping Spark Plug

| c CAUTION: Avoid injury! Before you remove spark plug: · STOP engine · Let engine cool |

IMPORTANT: Avoid damage! DO NOT clean spark plug with abrasives. |

M96036

1. Disconnect spark plug wire (A). Remove plug (B).

2. Inspect plug for wear or damage. Replace plug if needed.

3. Adjust gap: 0.76 mm (0.030 in.).

4. Install and tighten plug to 27 N·m (20 lb-ft).

5. Connect plug wire.

Cleaning Fuel Cap Vents

| c CAUTION: Avoid injury! Before cap is removed: · STOP engine. · Let engine cool. · DO NOT smoke while working on fuel system. |

M62527

1. Remove cap.

2. Clean vents (A) in nonflammable solvent.

3. Install cap.

Adjusting Carburetor

NOTE: The carburetor is calibrated by the engine manufacturer and should not require any adjustments.

If engine is operated at altitudes above 1829 m

(6,000 ft.), some carburetors may require a special high altitude main jet. See your John Deere dealer.

Possible engine surging will occur at high rpm when the machine is in neutral ('N') and the auger is disengaged. This is a normal condition due to the emission control system.

If engine is hard to start or runs rough, check the TROUBLESHOOTING section of this manual.

After performing the checks in the troubleshooting section and your engine is still not performing correctly, contact your John Deere dealer.

Checking Gearbox Lubricant

Auger gearbox has been lubricated at factory and SHOULD NOT require additional lubrication.

If for some reason the lubricant should leak out, or if the auger gearbox has been serviced; check lubricant.

M71588

1. Remove check plug (A).

2. If you cannot see grease, use a wire or plastic tie strap to check for grease.

· If you can see grease on wire or tie strap, do not add grease.

3. If necessary, add John Deere High Temperature EP Grease 100 gr (3-1/2 oz) maximum when gearbox is empty or an equivalent, such as:

· Benalene No. 372

· Shell Darina 1

· Mobiltem 78

· Texaco Thermatex EP1

4. Install check plug.

Adjusting Auger Drive Belt

IMPORTANT: Avoid damage! Before adjusting belt, check auger drive cable adjustment. (See Adjusting Auger Drive Cable in the section). |

NOTE: If you do not operate snowblower 25 hours during season, adjust auger drive belt at end of season.

1. Disconnect spark plug wire.

M60921

2. Loosen screw (A) on each side of belt cover (B). Remove cover.

M71569a

3. Hold down auger drive lever so idler pulley (C) is engaged. Check belt deflection. Belt should deflect 13 mm (1/2 in.) (D) with moderate thumb pressure.

4. Adjust belt, if necessary:

M96038

· Loosen nut (E). Move pulley (F) toward belt 3 mm (1/8 in.).

· Tighten nut.

· Check deflection again.

5. Check belt guides (G) adjustment. (See Adjusting Belt Guides in this section.)

6. Install belt cover.

Adjusting Belt Guides

1. Disconnect spark plug wire.

M60921

2. Loosen screw (A) on each side of cover (B). Remove cover.

3. Hold auger drive control lever down to handle.

M71575a

4. Measure distance between belt guide (C) and belt. Distance should be 3 mm (3/32 in.). If it is not, loosen guide mounting bolt (D), adjust guide, and tighten bolt.

M96038

5. Release control lever. Install cover. Connect plug wire.

Replacing Auger Drive Belt

M60921

1. Disconnect spark plug wire.

2. Loosen screw (A) on each side of cover (B). Remove cover.

M96038

3. Loosen nut (C). Move pulley (D) away from belt.

4. Loosen belt guides (E). Move them away from belt.

M96038

5. Remove belt (F) from engine drive pulley (G).

6. Remove top two housing bolts (H), and loosen bottom two bolts (I). Separate auger housing from engine frame hinging on bottom 2 bolts.

7. Remove brake arm (J) from housing. DO NOT remove spring.

8. Remove old belt.

9. Position new belt on auger pulley.

10. Install brake arm. Be sure brake arm is pushed into housing, and brake pad is seated in pulley groove.

11. Position belt onto engine drive pulley.

12. Install auger housing to engine frame with top two bolts. Tighten bottom two bolts.

13. Adjust belt. (See Adjusting Auger Drive Belt in this section.)

14. Adjust belt guides. (See Adjusting Belt Guides in this section.)

15. Install cover. Connect plug wire.

16. Check auger drive cable adjustment. (See Adjusting Auger And Traction Drive Cable in this section.)

Replacing Traction Drive Belt

1. Disconnect spark plug wire.

M60921

2. Loosen screw (A) on each side of cover (B). Remove cover.

3. Loosen belt guides. Move them away from belt.

M96038

4. Loosen nut (C) and move pulley away from auger drive belt (D).

5. Take auger drive belt off of engine pulley (E).

6. Pull and hold idler pulley (F) away from traction drive belt (G). Pull belt past pulley.

7. Remove belt from engine pulley.

8. Remove belt from between bottom of large pulleys.

9. Install new belt on bottom of large pulley and onto engine pulley.

10. Pull idler pulley toward you and slip belt past pulley.

11. Release idler.

12. Install auger drive belt on engine pulley.

13. Adjust auger drive belt pulley. (See Adjusting Auger Drive Belt in this section.)

14. Adjust belt guides. (See Adjusting Belt Guides in this section.)

15. Install cover. Connect plug wire.

16. Check traction drive cable adjustment. (See Adjusting Traction And Auger Drive Cable in this section.)

Adjusting Friction Wheel

| c CAUTION: Avoid injury! Snowblower may be heavy. If necessary, have another person help you stand snowblower on end. |

NOTE: Do this service when there is only a small amount of fuel in fuel tank.

1. Move speed selector lever to first (1) speed.

2. Stand snowblower on end of auger housing.

3. Remove bottom panel:

M60926

· Remove rear bolts (A).

· Loosen bolts (B).

· Remove panel.

M71581

4. Check position of friction wheel. Right side of disc drive plate (C) should be 76 mm (3 in.) (D) from center of friction wheel (E).

M60925

5. To adjust position of friction wheel:

· Loosen two nuts (F) on speed selector lever.

· Move friction wheel to proper position.

· When position is correct, tighten nuts.

6. Install bottom panel.

Replacing Shear Bolt

IMPORTANT: Avoid damage! Replacement shear bolts MUST BE the same as original shear bolts on your snowblower. · Softer bolts may shear too easily. · Harder bolts may not shear and may cause other parts of your snowblower to suffer damage. |

NOTE: Two extra shear bolts are in the bag of parts included with your snowblower.

1. Stop engine.

M71588

2. Remove broken shear bolt (A), if necessary.

3. To help prevent auger from rusting, lubricate auger shaft at two shear bolt points and at end of each shaft with a lightweight oil. Turn auger on shaft several turns to help distribute oil.

4. Line up holes in auger with hole in auger shaft.

M71579

5. Install new bolt with spacer (B) under bolt head. Fasten bolt with lock nut (C).

Reversing Scraper Blade

When edge of blade is worn, rough, or bent, reverse blade.

1. Raise snowblower. Put blocks under it.

M71585

2. Remove five nuts (A), lock washers, and bolts.

3. Reverse blade. Install and tighten hardware.

4. Remove blocks.

Adjusting Traction and Auger Drive Cable

IMPORTANT: Avoid damage! Also adjust traction and auger drive cables whenever belts are adjusted or replaced. |

To check adjustment:

M71572

· Pull on spring and remove cable end (Z fitting) (A) from bracket hole.

· Push control lever all the way forward so it contacts the plastic bumper.

· Pull cable straight and put end of cable-the Z fitting- on top of hole.

· Center of Z fitting should be between center and top of hole (B).

To adjust cable:

· Pull threaded end of cable out of spring.

M71586

· Turn nut (C) to adjust cable to correct length.

· Install cable end in bracket hole.

Lubricating Friction Disc Hub

M71581

Lubricate friction disc hub zerk (A) with one or two shots of John Deere Moly High Temperature EP Grease or an equivalent. (See Grease in this section.)

Lubricate Auger Shaft

NOTE: If you do not operate snowblower 25 hours during season, lubricate auger shaft at the end of the season before storage.

M71588

Remove two shear bolts (A). To help prevent auger from rusting, lubricate auger shaft at two shear bolt points and at the end of each shaft with a lightweight oil. Turn auger on shaft several turns to help distribute oil.

Lubricate Wheel Axle

| c CAUTION: Avoid injury! Snowblower may be too heavy for you. If necessary, have another person help you stand snowblower on end. |

NOTE: Do this service when there is only a small amount of fuel in fuel tank.

1. Stand snowblower on end of auger housing.

2. Remove both wheels.

M71573

3. Lubricate both axles (A) with John Deere Moly High Temperature EP Grease or an equivalent. (See Grease in this section.)

4. Install wheels.

Filling Fuel Tank Safely

| c CAUTION: Avoid injury! Handle fuel with care, it is highly flammable: · DO NOT refuel machine while you smoke, when machine is near an open flame or sparks, or when engine is running. STOP engine. · Fill fuel tank outdoors. · Prevent fires: clean oil, grease and dirt from machine. Clean up spilled fuel immediately. · Do not store machine with fuel in tank in a building where fumes may reach an open flame or spark. · To prevent fire and explosion caused by static electric discharge, while you fill tank, use a non-metal fuel container. If you use a funnel, MAKE SURE it is PLASTIC. Avoid using a funnel which has a metal screen or filter. · Use only clean approved containers and funnels. · Store oil and fuel in an area protected from dust, moisture and other contamination. |

IMPORTANT: Avoid damage! Avoid spilling fuel. Fuel can damage plastic and painted surfaces. DO NOT mix oil with gasoline. Unleaded gasoline with an octane rating of 87 or higher is recommended. Fuel tank capacity is 1.9 L (2 qt.). |

· Use only clean, fresh, unleaded regular grade gasoline.

· Remove any trash from top of fuel tank drain area.

· Use summer blended fuel for warm weather operation and winter blended fuel for cold weather.

· Never use fuel that is stale or has been stored for a long period of time:

Warm Weather - Maximum 60 days.

Cold Weather - Maximum of 90 days.

· Fill fuel tank at the end of each day's operation. This helps to keep condensation out of fuel tank.

1981 John Deere 826 Snowblower Parts Diagram

Oxygenated Fuel

Oxygenates (either ethanol or MTBE) are added to the gasoline. If you use the oxygenated fuel be sure it is unleaded and meets the minimum octane rating requirement.

The following are the EPA approved percentages of fuel oxygenates:

ETHANOL (Ethyl or Grain Alcohol): You may use gasoline containing up to 10 percent ethanol by volume.

MTBE (Methyl Tertiary Butyl Ether): You may use gasoline containing up to 15 percent MTBE by volume.

Filling Fuel Tank

| c CAUTION: Avoid injury! Allow engine to cool before refueling machine. |

1. STOP engine. If engine is hot let it cool several minutes before you add fuel.

M96036

2. Remove fuel tank cap (A).

826 John Deere Snowblower Engine

3. Fill fuel tank to 13 mm (1/2 in.) below bottom of filler neck to allow room for gasoline to expand.

4. Install fuel tank cap.

Check Tire Pressure

M62509

Check tires for damage.

Check tire pressure with an accurate gauge.

Tire pressure should be 110 kpa (15 psi).

John Deere 826 Walk Behind Snow Blower Service Manual

John Deere 826 Walk Behind Snowblower Technical Manual TM1234

174 Pages in .pdf format

28.5 MB in .zip format for super fast downloads!

This factory John Deere Service Manual Download will give you complete step-by-step information on repair, servicing, and preventative maintenance for your John Deere. The John Deere Service Manual is highly detailed with photos and illustrations to help guide you through every repair and troubleshooting procedure. This manual contains all you need to know to keep your John Deere working right and is the only service repair manual you will need. It will help you understand, care for, and lower the repair and maintenance cost for your John Deere.

John Deere 826 Snowblower Repair Manual

This John Deere 826 Walk Behind Snow Blower service manual is the same service manual used by professional John Deere technicians.

All pages are printable, so run off what you need & take it with you into the garage or workshop. Save money $$ by doing your own repairs! These John Deere Manuals make it easy for any skill level with these very easy to follow, step-by-step instructions! Instant download means no shipping cost or waiting for a CD to arrive in the mail…you will receive this John Deere Manual immediately via instant download on completion of payment via our secure payment processor. We accept all major credit/debit cards/paypal.

826 John Deere Snowblower Diagram